Specially developed for microwelding, the SPOT TIG SST allows for extraordinary versatiliy :

- Traditional TIG mode, with unrivalled weld quality and precision for both ferrous and non-ferrous materials, such as copper and bronze but also aluminum ;

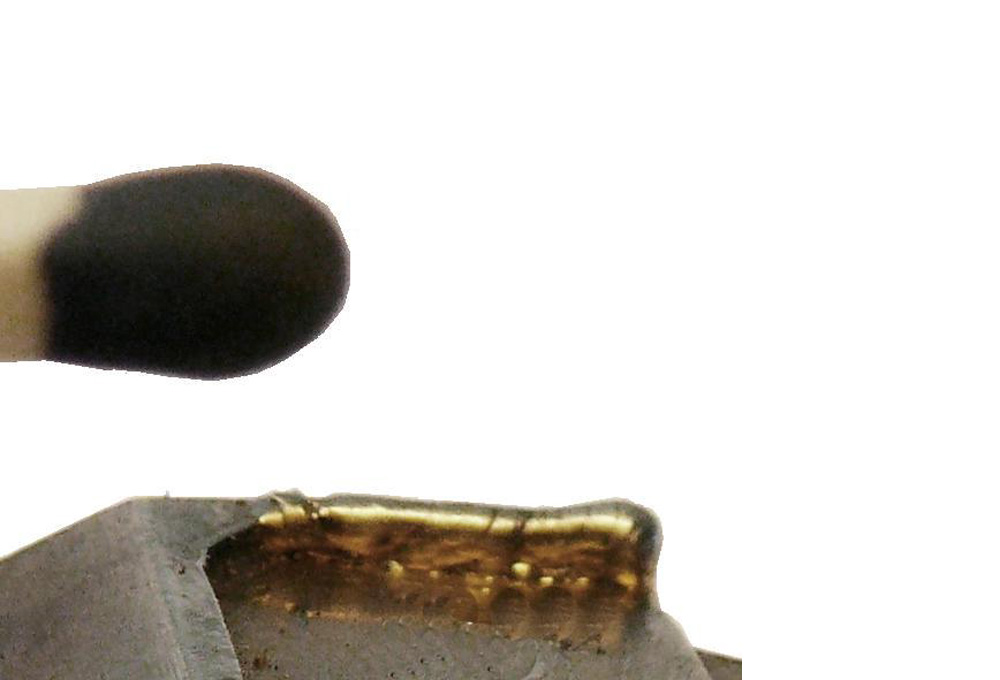

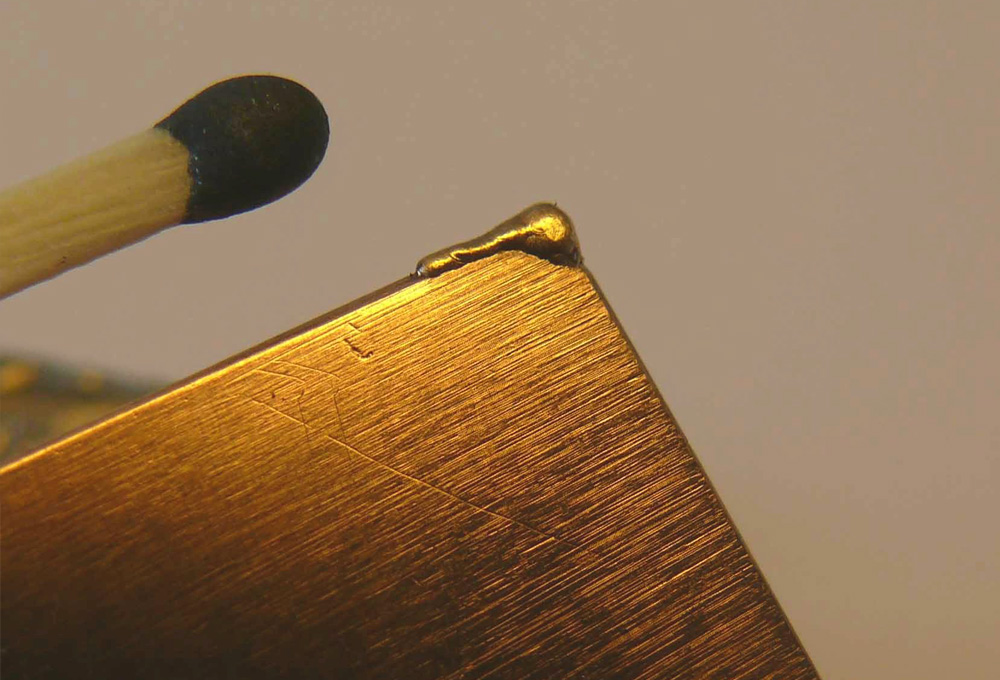

- Thanks to its specific SPOT mode, you can instantly transform your SPOT TIG device into an ultra-precise pulsed laser welding machine. SPOT mode enables you to carry out micro-pulse welding in just a few milliseconds, with perfect fusion quality and no overheating, for a result almost identical to that of a pulsed YAG laser ;

- All materials weld-able in TIG mode can be welded in SPOT mode: ferrous materials, copper and copper alloys, bronze and bronze alloys, aluminum ;

- Pulse duration is short (a few milliseconds) and factory configuration is easily adjustable by the user ;

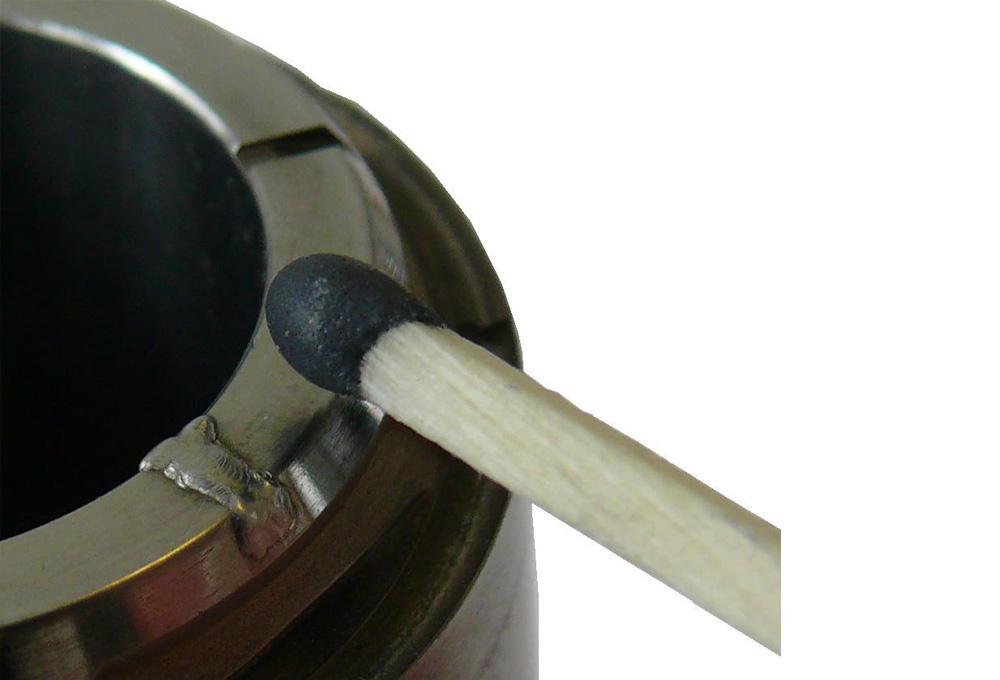

- Set-up is very simple; complex welds are easy and safe to carry out ;

- Very little heat is applied to the part and feathers and shrinkage are negligible meaning no deformation risk when carrying out complex welds or welds on very small parts ;

- Welds are discreet even on visible areas ;

- Welds are perfectly homogenous and resistant ;

- Welds are safer in hard-to-access areas ;

- Small-diameter laser welding wires (Ø 0.2 to 0.6mm) in all grades : titanium, steel, stainless steel, copper, bronze, aluminium, etc.